ข้อมูลเบื้องต้นเกี่ยวกับอุปกรณ์

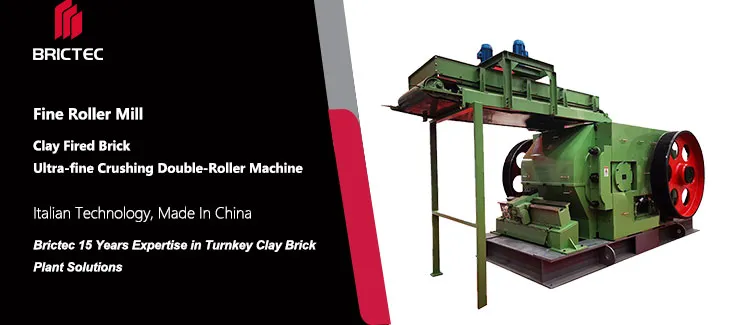

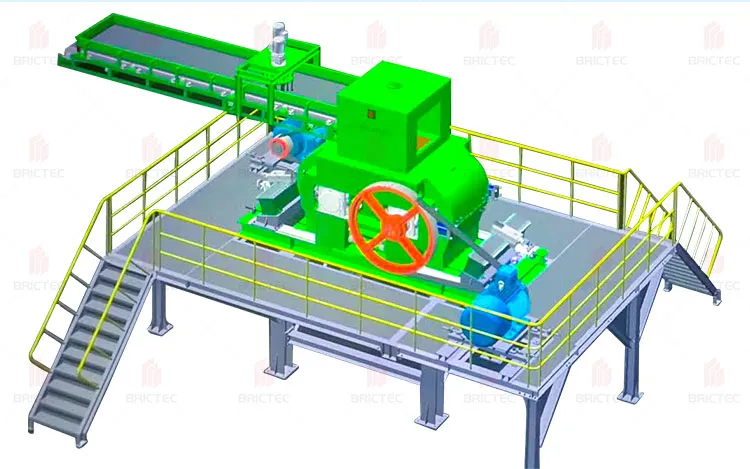

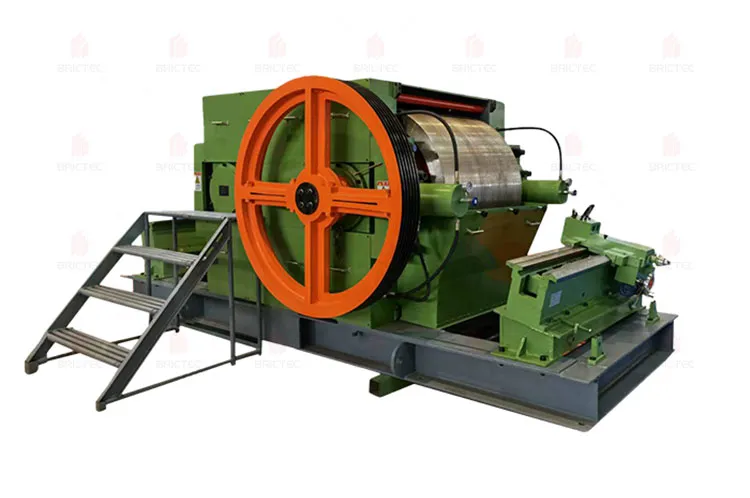

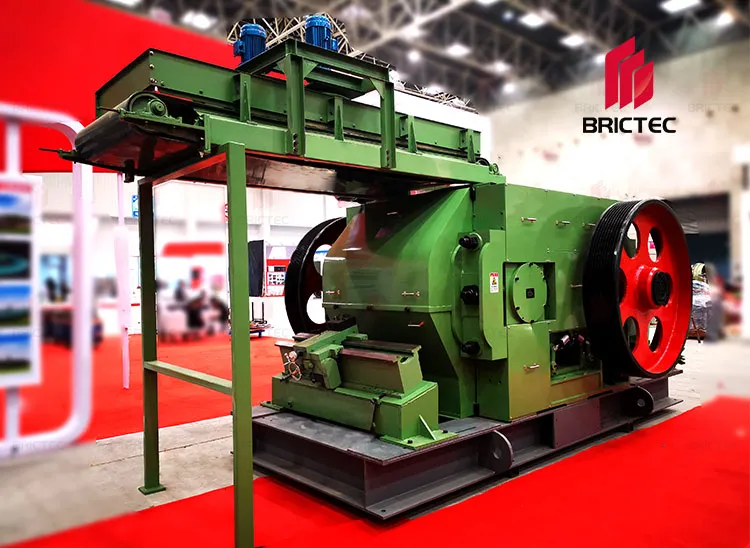

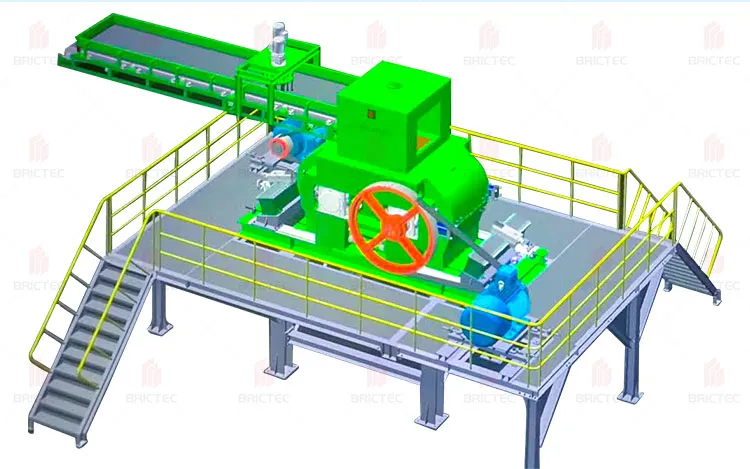

เครื่องบดแบบลูกกลิ้งคู่ละเอียดพิเศษสำหรับอิฐเผาจาก Shandong Qingmai เป็นอุปกรณ์บดประสิทธิภาพสูงที่ออกแบบมาโดยเฉพาะสำหรับอุตสาหกรรมอิฐและเซรามิก สามารถบดย่อยวัตถุดิบเพิ่มเติมได้ ไม่ว่าจะแห้งหรือเปียก ให้มีขนาดอนุภาค 0.5~1.0 มม. ซึ่งตรงตามข้อกำหนดของผลิตภัณฑ์ต่างๆ สำหรับลักษณะของวัตถุดิบ อุปกรณ์นี้ใช้เทคโนโลยีขั้นสูงของยุโรปรวมกับกระบวนการผลิตของจีน ทำให้มั่นใจได้ถึงประสิทธิภาพและความน่าเชื่อถือ

ข้อมูลเบื้องต้นเกี่ยวกับอุปกรณ์:

ข้อมูลเบื้องต้นเกี่ยวกับอุปกรณ์:

| รุ่น |

ความจุ (ลบ.ม./ชม.) |

ขนาดลูกกลิ้ง (มม.) |

ขนาดอินพุต (มม.) |

ช่องว่างลูกกลิ้ง (มม.) |

ขนาด (มม.) |

น้ำหนัก (ตัน) |

กำลังไฟ (กิโลวัตต์) |

| GS1000×800 |

25-40 |

Φ1000×800 |

≤25 |

1.5-3 |

6100×3900×1600 |

16.8 |

37+30 |

| GS1000×1000 |

30-50 |

Φ1000×1000 |

≤25 |

1.5-3 |

6200×4200×1700 |

22.4 |

90+75 |

| GS1200×1000 |

30-55 |

Φ1200×1000 |

≤25 |

1.5-3 |

7300×4300×1800 |

24.5 |

110+75 |

| GS1400×1200 |

40-60 |

Φ1400×1200 |

≤25 |

1.5-3 |

7800×6500×2300 |

33 |

160+90 |

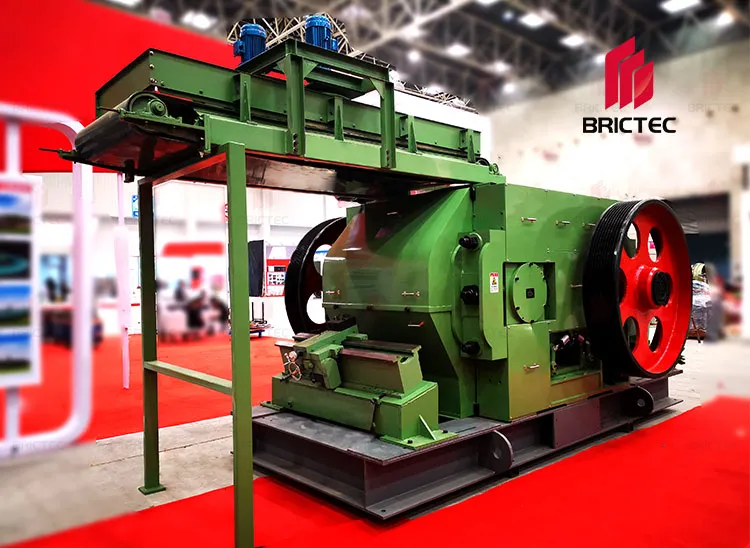

คุณสมบัติของอุปกรณ์

(1) ความสามารถในการบดย่อยละเอียดพิเศษ: ช่องว่างลูกกลิ้งขั้นต่ำสามารถเข้าถึง 0.8 มม. โดยมีความละเอียดของผงที่สามารถทำได้ 0.5 มม.

(2) ช่องว่างลูกกลิ้งที่ปรับได้: ช่องว่างลูกกลิ้งสามารถปรับได้ตลอดเวลาภายในช่วง 0.8~2.0 มม.

(3) ฟังก์ชันความเร็วต่างกันของลูกกลิ้ง: โดยการปรับความแตกต่างของความเร็วของลูกกลิ้ง สามารถปรับปรุงผลการบดผงได้

(4) อุปกรณ์เสริมต่างๆ: ติดตั้งอุปกรณ์เจียรลูกกลิ้ง, อุปกรณ์ป้องกันการจัดเก็บพลังงาน, อุปกรณ์ขูดโคลนแบบนิวเมติก และระบบความปลอดภัยในการควบคุมไฟฟ้า

(5) วงแหวนลูกกลิ้งที่มีความแข็งสูง: ความแข็งของวงแหวนลูกกลิ้งสามารถเข้าถึง HRC60 ขึ้นไป

ข้อดีของอุปกรณ์

(1) ประสิทธิภาพการบดย่อยสูง: อุปกรณ์สามารถบดย่อยวัตถุดิบได้อย่างมีประสิทธิภาพให้ได้ขนาดอนุภาคที่ต้องการ ซึ่งตรงตามข้อกำหนดของกระบวนการในภายหลัง

(2) การปรับตัวที่แข็งแกร่ง: มีการปรับตัวที่แข็งแกร่งกับวัสดุที่เหนียวและเปียก และไม่ค่อยเกิดการอุดตัน

(3) การใช้พลังงานต่ำ: อุปกรณ์ทำงานโดยใช้พลังงานต่ำ ช่วยลดต้นทุนการผลิต

(4) การบำรุงรักษาที่สะดวก: การออกแบบช่วยให้สามารถเปลี่ยนวงแหวนลูกกลิ้งได้โดยไม่ต้องถอดตัวเรือนแบริ่ง ซึ่งอำนวยความสะดวกในการบำรุงรักษาอุปกรณ์

(5) ประสิทธิภาพด้านสิ่งแวดล้อม: เสียงรบกวนต่ำและการปล่อยฝุ่นน้อยที่สุดระหว่างการทำงาน ซึ่งตรงตามข้อกำหนดด้านสิ่งแวดล้อม

โครงสร้างอุปกรณ์

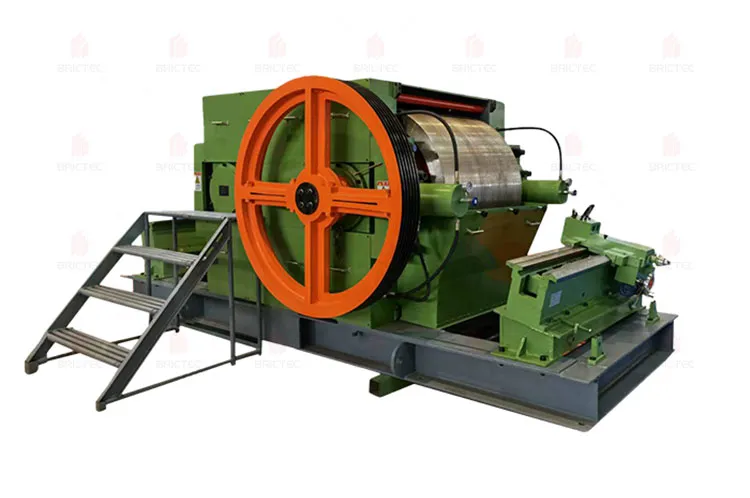

(1) ระบบลูกกลิ้ง: ลูกกลิ้งสองตัวที่หมุนสวนทางกันเป็นส่วนประกอบหลักของอุปกรณ์ ซึ่งรับผิดชอบในการเฉือนและการบดอัดของวัตถุดิบ

(2) ระบบขับเคลื่อน: ติดตั้งมอเตอร์และตัวลดความเร็วประสิทธิภาพสูงเพื่อให้กำลังไฟที่เสถียรแก่ลูกกลิ้ง

(3) อุปกรณ์ปรับ: ใช้เพื่อปรับระยะห่างระหว่างลูกกลิ้งเพื่อควบคุมขนาดการบดย่อย

(4) โครง: โครงเหล็กที่แข็งแรงช่วยให้มั่นใจถึงเสถียรภาพของอุปกรณ์ระหว่างการทำงาน

(5) ระบบป้องกันไฮดรอลิก: เมื่อวัตถุแข็ง เช่น โลหะ ผ่านลูกกลิ้งในโคลน ระบบป้องกันไฮดรอลิกจะดึงลูกกลิ้งกลับอย่างยืดหยุ่นภายใต้การกระทำของแรงผลักดันเกินพิกัด ปกป้องผิวลูกกลิ้ง

(6) อุปกรณ์ขูดโคลนแบบนิวเมติก: ติดอยู่กับพื้นผิวของผิวลูกกลิ้งเบาๆ อย่างต่อเนื่อง ขูดดินเหนียวบนพื้นผิววงแหวนลูกกลิ้งออก เพื่อให้แน่ใจว่าพื้นผิวลูกกลิ้งเรียบและแบน

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!